Low investment costs and an improvement of the working conditions!

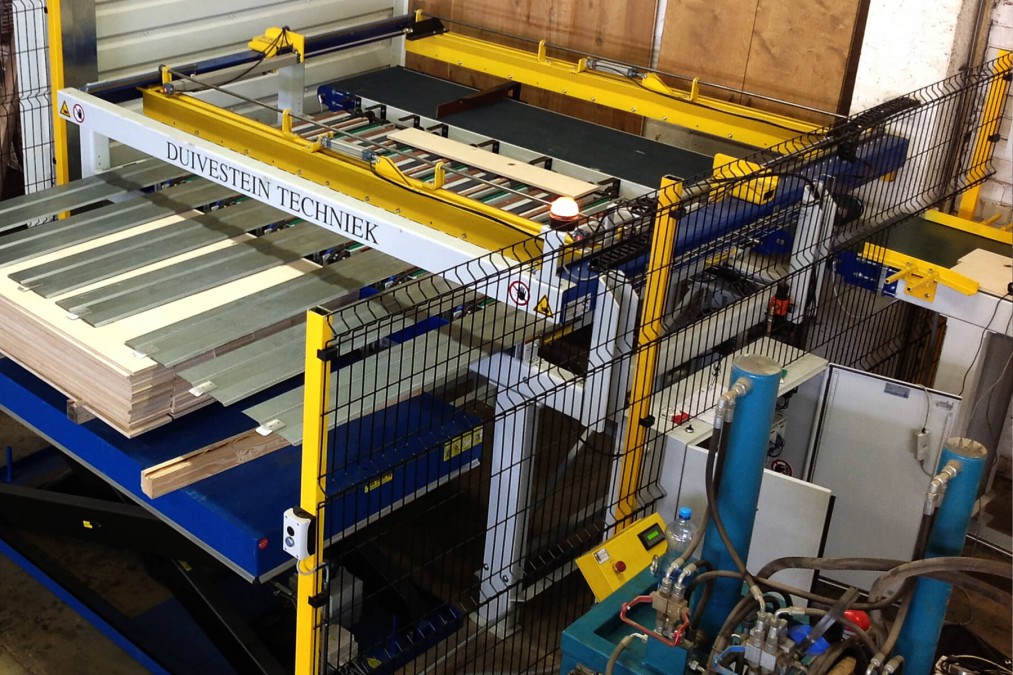

HS Stacking machine

The HS stacker is an automatic stacking machine that can stack workpieces coming from, for example, a four-sided planing machine. The workpieces can be stacked on pallets or beams.

The workpieces can be adjusted in height and width as desired. The HS stacking machine can also be placed behind a crosscut saw and a finger jointing machine.

Each manufacturer uses different materials of different sizes. The HS stacker is therefore also available in different versions.

Specifications

- Stacking of planks and beams

- Speed up to 25 pieces per minute

Investment in a HS stacker

The HS stacker has been developed with the idea of achieving a return for you as quickly as possible. The payback time of an HS 2200 stacker is approximately one year. The additional advantage is that the machine is easy to install and program. Furthermore, the programming system is designed in such a way that it can be operated without any prior training. The competitive price and ease of use make it possible for everyone to automate the production process.

Advantages of an HS Stacker

- Low investment

- Fast payback period

- Improvement of working conditions

- Low maintenance

- Can be used immediately

- Cost saving

- Simplification of the production process

- From two to one man operation

Where the HS Stacking Machine can be used

- Four-sided planer

- Cut-off saw

- Profiling machine