Super fast stacking of boards and beams!

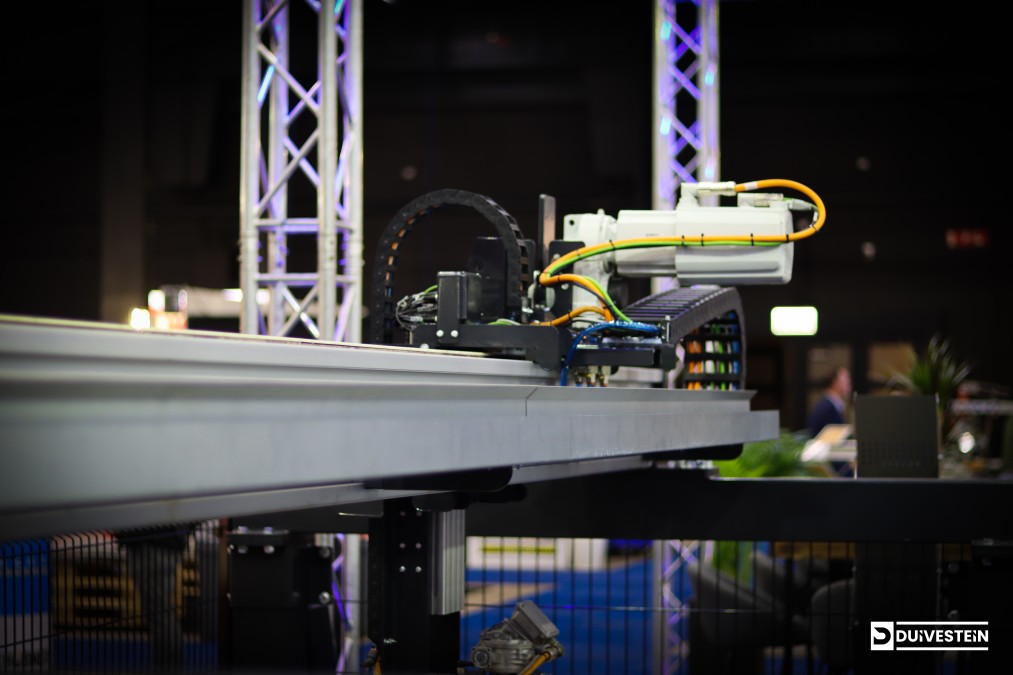

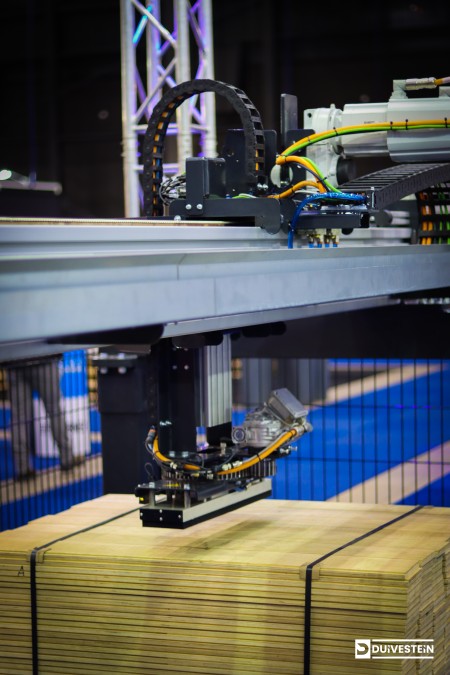

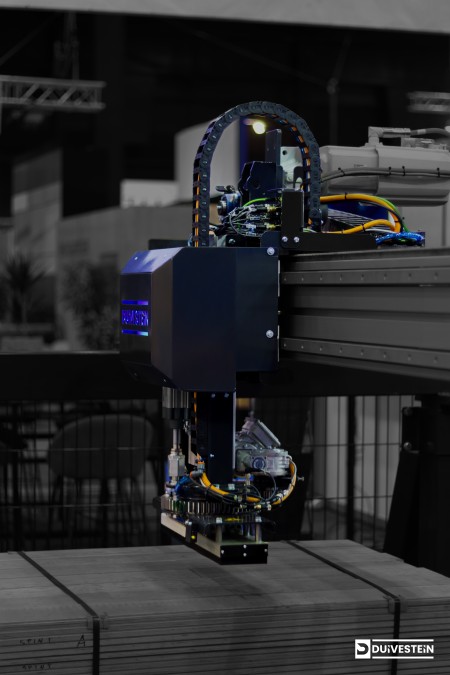

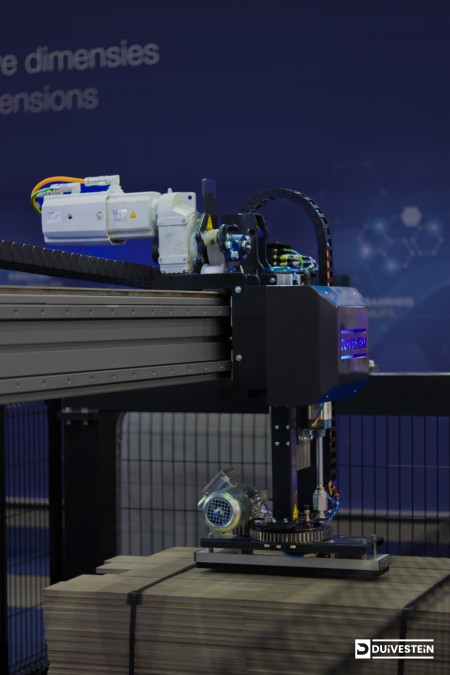

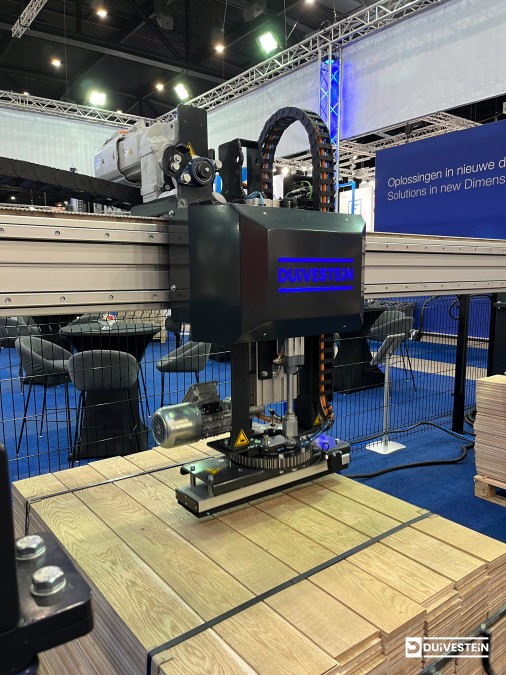

RP4 Stacking machine

For more than 30 years, Duivestein has been developing various stacking machines tailored to customer requirements. With great pride we have added a new stacking machine to the RP family. Compared to the RP-3, the RP-4 stacking machine has been completely renewed by means of the newest techniques.

One notable feature and innovation is that the RP-4 stacker stacks beams and boards up to twice as fast as its predecessor, the RP3 stacker.

Operation of the RP4 stacking machine

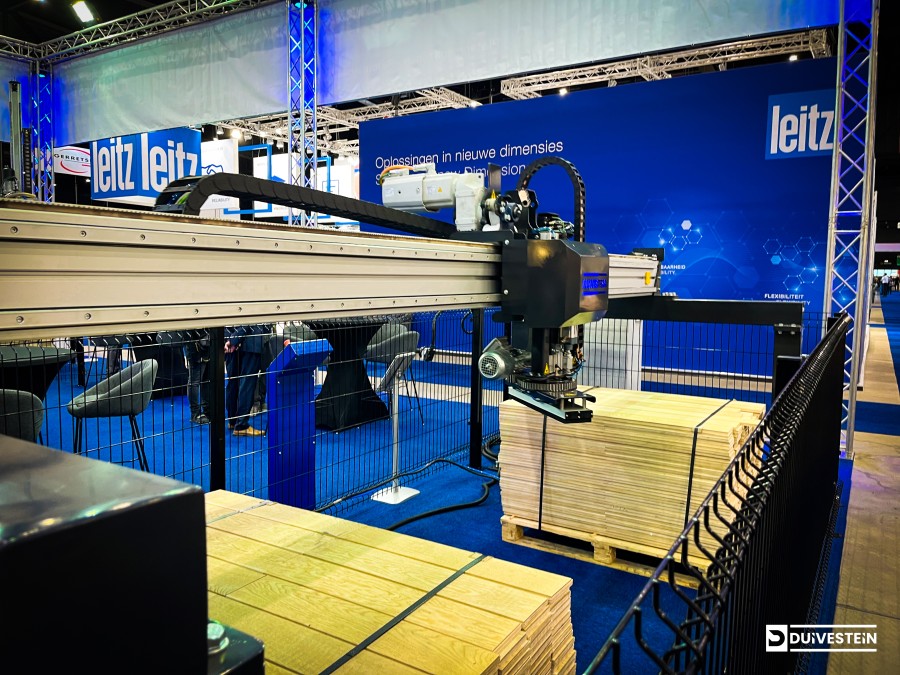

The stacker feeders work with vacuum technology. They can be placed in front of and/or behind practically every production machine. These include sawing, sanding, milling, edging, painting and all-rounders. Using various selection and expansion options, such as automatic bearings and cross transfer systems, a fully automatic production line is made possible.

The RP4 automatic stacker is an upgrade of the RP3 automatic stacker. The handling speed of the RP4 stacker is 2x faster than the RP3 stacker.

Specifications

- Stacking and feeding of boards and beams

- Speed up to 10 operations per minute at a weight of up to 25 kg

- Maximum handling weight is 50 kg

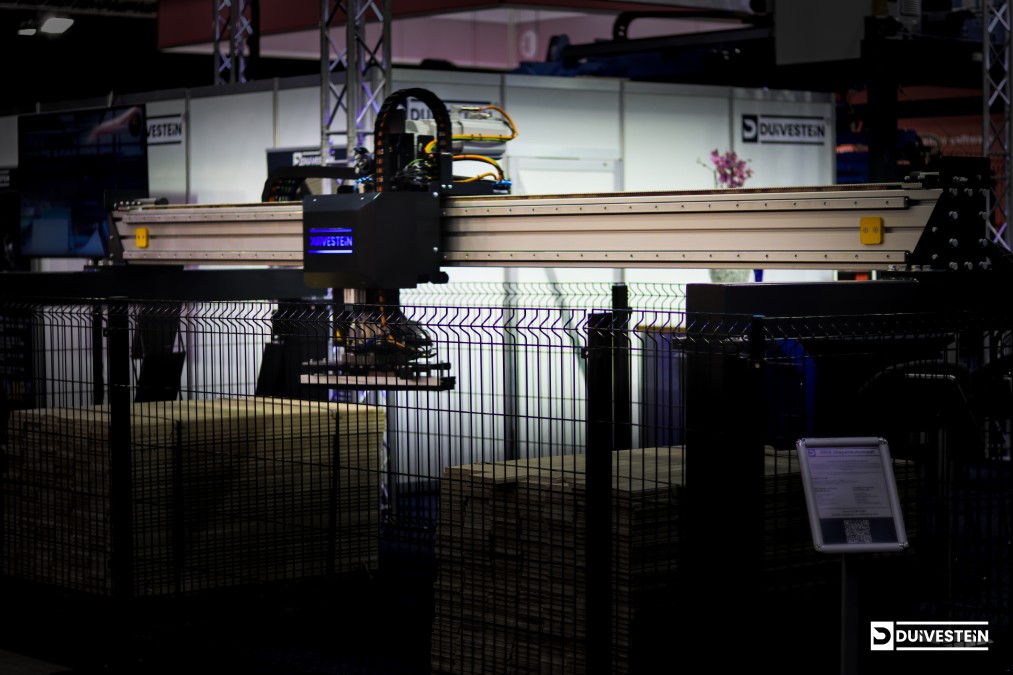

RP4 Stacking machine use as a stacker

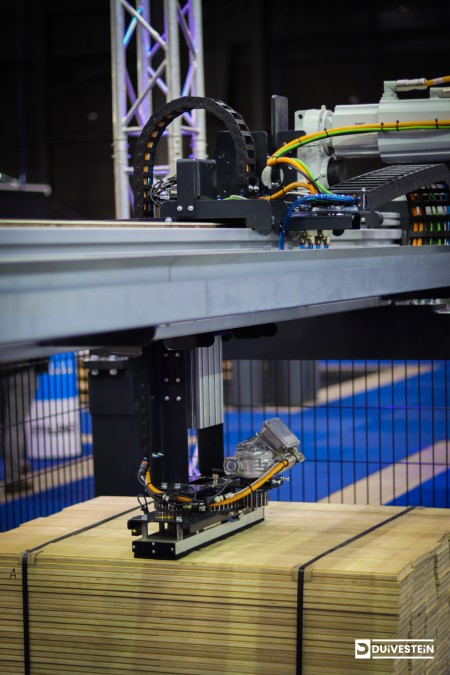

Workpieces coming out of a production machine are transported through the conveyor and placed under the vacuum pad in such a way that it can grab the workpiece. When the workpiece is in place, the lifting column, will bring the two beams with the vacuum pad, down on top of the workpiece. The vacuum valve will then turn on and the workpiece will be sucked against the vacuum pad. When the vacuum's negative pressure is high enough, the lifting column with the vacuum pad will rise again, taking the workpiece with it. When the lifting column is completely at the top, the lifting column will move to the left in the direction of the deposit. Once there, the lifting column will stop and the vacuum pad will release the workpiece. After this, the lifting column will move to the right again and stop above the conveyor at a fixed set value. If there is a new workpiece under the vacuum pad, this cycle will be repeated and the workpiece will be placed next to the previous workpiece. The machine will thus form a layer of the workpieces. After each layer, a new layer is formed until one reaches the desired height of the stack. To strengthen the stack, the machine can stack offset, giving one a solid package.

RP4 Stacking machine use as input device

In this case, the machine works in exactly the opposite direction. The parts are picked up from the take-out position or deposit position and deposited on the conveyor belt.

Investment in an RP4 stacker

The RP4 automatic stacker was developed with the idea of achieving a return on investment for you as quickly as possible. The payback time of an RP4 stacker is about one year. An additional advantage is that the machine is easy to install and program. Furthermore, the programming system is designed to be operated without any prior training. The competitive price and ease of use make it possible for anyone to automate the production process.

Benefits of an RP4 Stacker

-

Low investment

-

Fast payback time

-

Improved working conditions

-

Low maintenance

-

Can be used immediately

-

Cost-saving

-

Simplification of the production process

-

From two to one man operation

Where the RP4 Stacking machine can be deployed

- Four-sided planer

- Cut-off saw machine

- Pallet line

- Stamping machine

- Sheeting machine

- Packing line

- Wide belt sander

- Finger welding machine